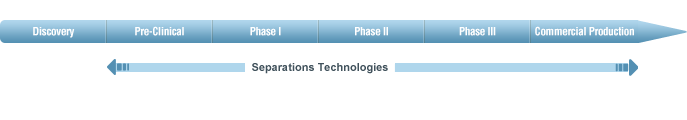

Separations TechnologyOur unique separation capabilities and development-oriented staff can resolve your chromatography challenges when chromatography simply cannot be avoided. We have development through commercial scale equipment to accommodate gram-scale purifications through multi-metric ton quantities. SFC:Supercritical Fluid Chromatography utilizes supercritical CO2 as a replacement for traditional non-polar organic solvents and is particularly useful for purification of materials with poor solution stability.  Pharma Materials houses the largest SFC unit in North America, which is built and operated in full compliance with cGMP guidelines. This unit, the SUPERSEP 200, utilizes 20 cm ID columns with a CO2 recycling system to minimize the solvent requirements for the purification. Pharma Materials houses the largest SFC unit in North America, which is built and operated in full compliance with cGMP guidelines. This unit, the SUPERSEP 200, utilizes 20 cm ID columns with a CO2 recycling system to minimize the solvent requirements for the purification.

Purified fractions are separated from CO2 in gas-liquid cyclonic separators. The pressure is dropped to precipitate/liquefy the solutes in the cyclones. Preparative HPLC:We employ preparative HPLC for the purification of multi-component mixtures when traditional purification means aren’t viable. Our systems utilize 10 to 50 cm ID columns with pumps that produce flow rates up to 600 L/hr. The 50 cm column holds approximately 50 kg of solid phase and is custom packed on site with commercially available phase. The eluant handling systems we presently have can utilize automated rotary evaporators or thin film evaporators (TFE) depending on the process needs. We have two one-square-foot TFE units that support small-scale chromatography and two five-square-foot TFE units to support chromatography using the 30 and 50 cm columns.

|